Heating optimization:

Gas, oil, wood and pellet plants

- efficient combustion

- Increasing the efficiency

- lowers the exhaust gas temperature (more power remains in the system)

- Less exhaust fumes

- 10 to 20 % resource saving

Retrofitting instead of buying a new heating system

Mode of operation:

This is similar to the BE-Fuelsaver, but it is only a small metal rod with a length of 30mm and a diameter of 8mm. To distinguish it has a hole in the middle. The BIO-ENERGETIC-Oil-Saver is fixed with a cable tie on a thin part (thin-walled) of the supply line to the oil burner, or even better directly in the oil filter (simply unscrew the sight glass at the bottom when the heating is switched off).

Application:

It is recommended to have the burner readjusted after 6-8 weeks (throttle the air supply) and possibly reduce the oil nozzle diameter by 0.1-0.5 mm so that it can be adapted to the new combustion conditions. Often the argument comes that the furnace soots up if you reduce the nozzle. However, this is not the case, as the modified combustion is more efficient and the carbon is burned better. The practice shows it !

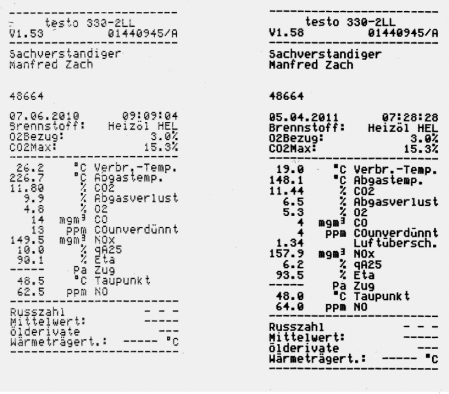

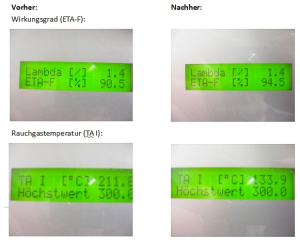

From the measurement on the right, you can see that the efficiency increases and the exhaust gas temperature decreases. Carbon monoxide (CO) is also decreasing. An excess of air is created, which should then be readjusted after approx. 6-8 weeks, as described above, in order to further optimize the system. It was also possible to use the pen to make old oil heating systems fit again, which no longer achieved the required efficiency of 90% (= exhaust gas loss of less than 10%) and emitted too much CO. A simple way to "renovate" old equipment.

Measurement

Exhaust gas temperature has dropped 78 degrees and CO levels have been reduced.

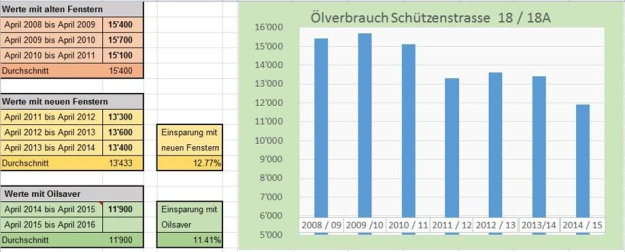

"The BE-Oilsaver brings almost as much as replacing the windows for 100,000 CHF!"

Reports customer Matthias Örhli to N-G partner Gregor von Drabich:

"Dear Gregor, I think the two winters were roughly comparable. Yes, the new windows cost a tiny bit more than two Oilsaver . J It is a block of 12 apartments. Six 3 1/2-room and six 4 1/2-room apartments each. Year of manufacture 1980. The old windows were double-glazed wooden windows, some of which were already drafty. We decided to replace all the windows on the entire block with triple-glazed plastic windows at the 2009 owners' meeting, which was finally completed in the fall of 2010. That cost pretty much CHF 100,000 for the whole block.

Here are the savings with windows (12.8%) and then with BE oil savers (11.4%):"

It is now obvious that after the fuel oil, gas is also optimized for combustion. Therefore, the BE gas saver was developed next:

Application:

This is a hexagon about 2.5 cm long, which is mounted with cable ties on the gas supply near the burner. This can also happen in the pipe inside the gas boiler. To do this, you have to open the cover and can fix the pin there on the usually found stainless steel line with two cable ties.

BE-Gassaver in a bakery saves €1,000 a year and a new heating system by €6,000.

"We work in the third generation as a country bakery in the Löwenberger Land, so since 1927. On average, we are always 10 people in operation. There are still some pastries that are very individual and can be found only with us. However, this requires a lot of energy, which we generate with natural gas. That's how I became aware of the Gassaver, which is supposed to reduce not only consumption, but also the exhaust fumes from our heaters, which is also important to me. I have been using two Gassavers for half a year now and I must say I am very satisfied. The bakery has a very constant energy demand and after 6 months I have already saved 500 € there, really incredible!

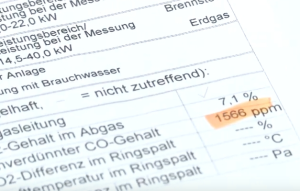

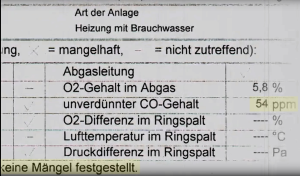

And my private heating system had very poor exhaust values (CO 1566 ppm) and has repeatedly failed the inspection by the chimney sweep in recent years and should now have been replaced. But with the Gassaver, I achieve the new exhaust values (CO 54 ppm) and can still keep the heater, which saves me an investment of many thousands of euros. The values without service are still great after one year. Thanks for the good work and please keep it up!

Sincerely Fred Plessow, 16775 Teschendorf fred.plessow@web.de"

Application:

The bio-energy wood chip saver is stuck somewhere on a cleaned spot on the conveyor shaft or pellet hopper of the heating system. It takes about 3 to 4 weeks to reach the maximum effect.

Change in wood heating for general cargo - Mr. Jungwirth reports:

"During a presentation in the municipality of Petzenkirchen, I got to know the technology of NewGeneration Bio and its products and spontaneously decided to buy the wood saving hologram and put it into operation the same day. On Mr. Bieder's recommendation, I put the sticker on the bottom of my wheelbarrow, where my daily supply of logs is stored. After a week, the following parameters have changed on the display of my heating system.

Efficiency has increased from 91 to 93% and residual oxygen from 4 to 6.5%. CO has dropped from 16 to 13.9% and flue gas temperature from 200 to 150 degrees.

After 2 weeks, the efficiency has improved again by 1.5% to 94.5% and the CO value has dropped from 13.9% to 13%. Visually particularly well visible is the change of the flame, this has changed from its original shape high and orange to red to small to barely visible and bright.

I can not yet report on an effective consumption savings, I think that will then show the complete heating period!

With best regards

Josef Jungwirth / organic farm / Baumbach No. 11 / 3281 Oberndorf / 0664 73548980 / josef-jungwirth@aon.at"

![]() You can find more customer proofs and measurements, as well as a solution for firewood in the store

You can find more customer proofs and measurements, as well as a solution for firewood in the store